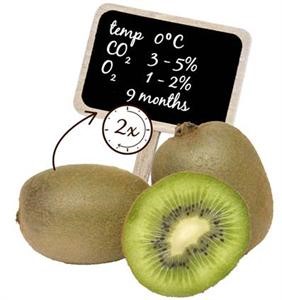

Fruit varieties that are sensitive to ethylene (under CA conditions), such as kiwis, require an ethylene converter. The ethylene converter from Van Amerongen removes ethylene from the cool cells using catalytic combustion; ethylene can thus be maintained at any required level, both in terms of a ppm or ppb range. The use of the Swing Term principle, actually a huge heat exchanger, means that purified air is only slightly heated. The ethylene converter uses oxygen to convert ethylene into CO2 and water, both inert substances.

Ethylene converter for;

- Maximum cooling of air, via top quality heat exchanger (Porcelain honeycomb);

- High catalytic value via high platinum aluminium granules (0.6 g kg-1);

- Low optimum combustion temperature of 250°C;

- A temperature difference between ingoing and outgoing air of <5°c.

Advantages of our Porcelain Honeycomb heat-exchanger compared to ordinary ceramic balls or grains (split):

- Improved thermal efficiency;

- Reduced pressure loss over thermal bed

- Quicker heat exchange;

- Reduced weight.